No matter how many years of experience you may have about setting up the network infrastructures, it comes to naught if you still don’t choose pre-terminated fiber cables while laying out. By choosing between a pre-terminated Fiber Trunk, Harness, and Patch Cables, you not only reduce the installation time considerably (around 60%) but also cost involved in manually testing every termination. Even then, the knowledge of where to use which type of fiber optic cable to implement at what instance is something that most people tend to miss out on.

Types of Fiber Optic Cables

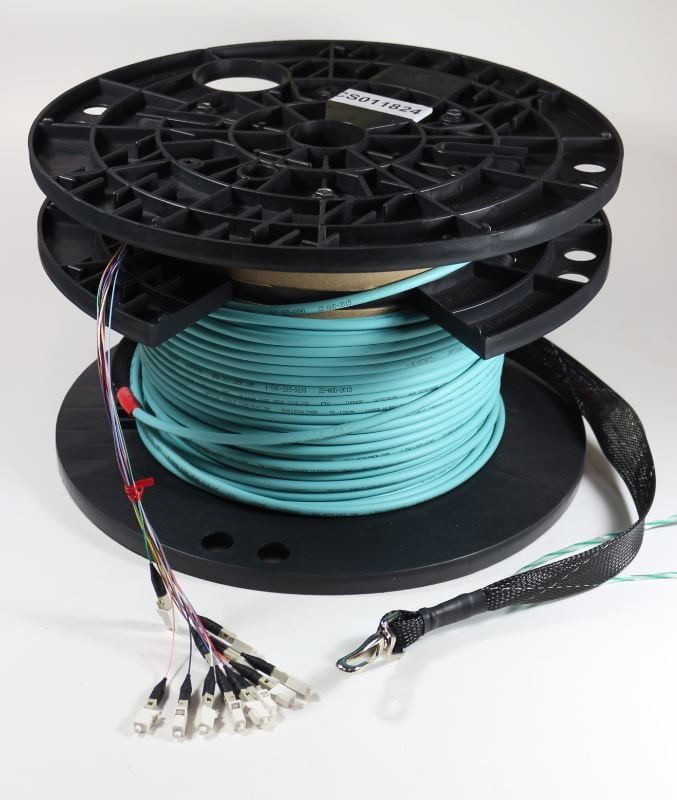

Fiber Optic Trunk Cable

A fiber optic trunk cable is generally a set of multiple fibers ranging from 4 to 144 fibers bunched together in a single cable. This makes the trunk cable to support multiple users at the same time without running individual fiber for each user. This type of cable is usually the backbone of the cabling infrastructure and the vital source of connection between the server & different appliances such as routers, switches, or patch panels.

Fiber Optic Harness Cable

A fiber optic harness cable is generally the fiber component that follows a fiber optic trunk cable. The harness is to break the multiple fibers into pairs of 4,6,8 or 12 discrete connectors. A fiber optic harness cable is generally used to feed the connectors into active equipment. One thing to keep in mind while purchasing a harness cable is that each leg of the connector end should be either identical in length or staggered 30mm (1.18”) longer than the outer tube.

Fiber Optic Patch Cable

A single cable used to connect devices with a patch panel is commonly termed as Fiber Optic Patch Cable. Depending on the devices to connect the fiber optic patch cable can be:

- Same connector type fiber patch cable: The fiber optic patch cable with the same type of connector on both ends i.e. ST, SC, LC, FC, etc.

- Hybrid fiber optic patch cables: The contrary version of the same connector, this fiber optic patch cable has different connectors on each end.

Categorization Based On Connector Polishing

Since light is the medium of transmission, it is important to make sure the fiber cable should be free from leaks. This is especially important when two different fiber cables need to be connected with each other (especially in single-mode fiber). So the end of each fiber optic needs to be polished in a way that the overall loss in the form of reflection back is less than at least -60dB. The categorization based on the connector polished is:

- Flat Contact

- Physical Contact

- Ultra Physical Contact

- Angled Physical Contact

- Flat Contact: The most common logic is to polish the edges of each fiber flat. This way the ends connect seamlessly and the signal reflected back is less than -30dB.

- Physical Contact: In this type of contact, the edges of each optical fiber is polished so that the edges are a slightly curved and small area of contact. This ensures only the main light signal is transmitted and the back reflection is reduced less than -35dB

- Ultra Physical Contact: This type of contact is a sharper version of the previous contact. The contact is sharper and reflection back is lesser than -55dB.

- Angled Physical Contact: In this type of contact, the edges are polished in an angled way so that seamless connection happens. The signal reflection back is lesser than -65dB.

Takeaways

- Trunk cable is the base of every network infrastructure.

- Harness breaks the fiber cables into smaller pairs

- The amount of signal loss depends on the types of contact polishing.

Leave a Reply