The benefits of programmable logic controllers are well documented. However, choosing one for a particular system must be done carefully, lest you wind up with a solution capable of far more than your system needs, far less, or one using the wrong technology. Nailing it can be a tricky thing to do. However, reviewing these things to consider when choosing a PLC will serve you well in that endeavor.

1. What Do You Need It to Do?

The last thing you want is an answer in search of a question. Carefully review the requirements of the system — taking some time to figure out exactly what you want it to do — will help you best determine what you need. Try to reduce each task you want the PLC to perform down to its constituent elements. This will help you gain a better understanding of the functions you need the controller to perform so you can balance your requirements against the capacities of the device.

2. How Many I/Os Need Accommodation?

You’ll need to know types in addition to numbers. This will help you determine the best chassis size for your application as well as use the controller to its fullest capabilities. This means you’ll need to consider each function and the type of device performing it. Do you have any special operations that might require discrete logic? What about advanced functions?

3. What Are the Electrical Requirements?

You’ll have power going into components and coming out of them. You’ll also need to get a handle on the incoming power for the control system as well as the output voltage and current for each device in the system. The PLC you choose must be capable of managing this effectively.

4. How Much Processing Power Is Needed?

Computing its programming in a logical and timely matter is critical to the proper functioning of the system over which a PLC has authority. How fast does the system operate when it’s performing at peak efficiency? Is there a need to detect time-critical functions? Will the output of encoders or low-flow meters need interpretation and response? This is an essential consideration as it is critical to the proper functioning of the system. An underspecified PLC can slow the system down to the point of inefficiency, or even cause damage. An over-specified device can add unnecessary expense. The goal should be to get a controller that is only moderately over-specified in case you also need it to scale to adapt to future requirements.

5. Can It “Converse” with Every System Component?

Communication protocols often vary from device to device. It’s important to select a PLC capable of communicating fluently with every component of the system with which communication is relevant. Whether gathering and interpreting data from a sensor or setting the parameters of a servo, the availability of standard network connection is absolutely essential. Some PLCs have communication ports configured to accept add-on modules. Others have internal capabilities. Does the PLC also need to accommodate Ethernet connections? How adaptable is this aspect of the controller? The more flexibility it provides, the better off you will be.

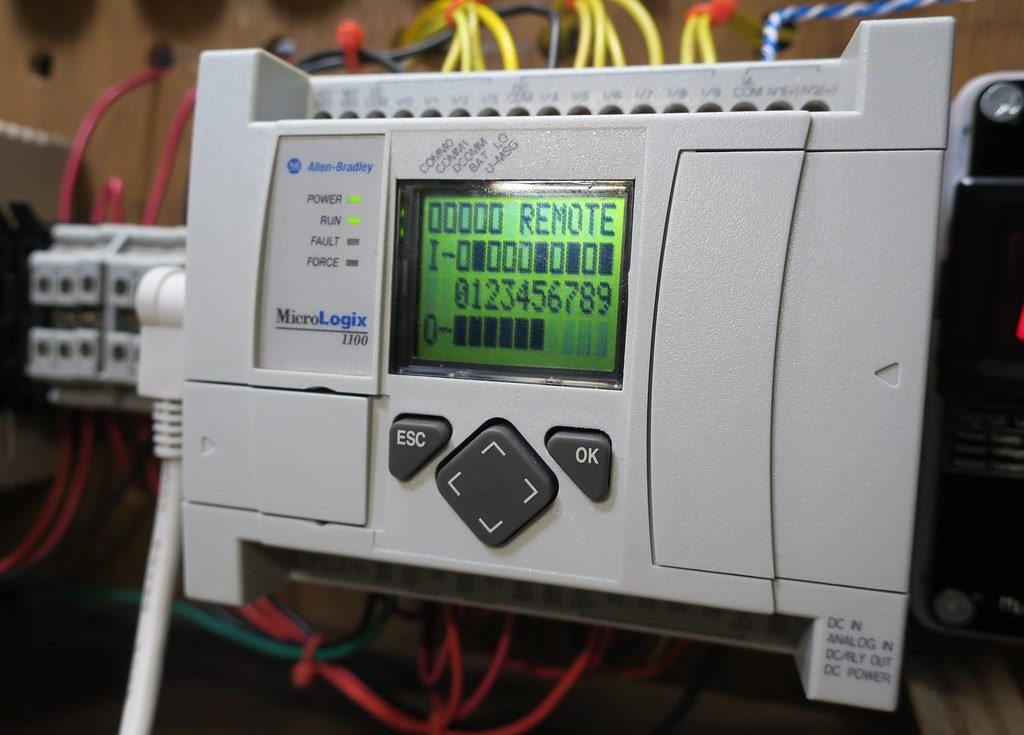

6. Is the Operator Interface Logical?

To function properly, the PLC will need a human being to tell it what it’s supposed to be looking for and how to respond. Interfaces include buttons, pilot lights, numeric displays, and touchscreens. Whatever its protocols, the interface needs to be readily understood and logical. An experienced user should be able to just look at it and figure out how to get it to operate. If you’re specifying a new controller for an existing system, make every effort to accommodate the I/Os and protocols it is currently using.

7. Where Will It Be Located?

Will you need to house the controller in an instrument panel enclosure to protect it from the physical environment in which it is placed? Are there high temperatures, dust or other potential contaminants with which the device will need to contend?

8. The Cost Factor

It is entirely possible to pay more for a controller than the system it is installed to protect. However, specifying such a device isn’t likely to get past the bean counters in your organization. Therefore it’s critical to find a PLC capable of fulfilling your needs, the cost of which is in line with the system it will administer.

Keeping these things to consider when choosing a PLC will help you specify the best available solution for the needs of your facility.

Tech content on this site may include contributed articles and partnerships with industry voices. Learn more in our Editorial Policy.